Introduction

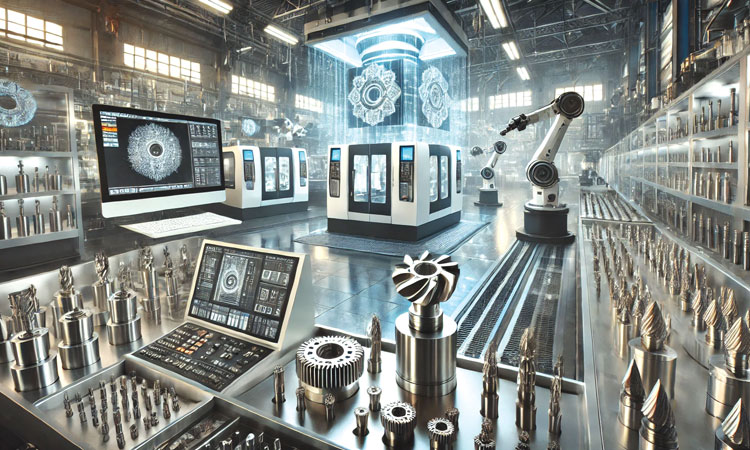

In today’s fast-paced manufacturing world, precision isn’t just a competitive advantage—it’s an expectation. As industries from aerospace to medical technology demand increasingly exact specifications, metal cutting has evolved from a basic fabrication task into a sophisticated science. The push for tighter tolerances, cleaner cuts, and faster production times has driven innovation in both technique and technology. What was once a manual, time-intensive process is now a digitally optimized cornerstone of modern manufacturing. This article examines the emergence of precision metal cutting, the technologies driving it, and the pivotal role it plays in shaping the future of high-performance industries.

The Rise of Precision Metal Cutting in Modern Industry

Modern industry stands at the intersection of rising expectations for performance, reliability, and aesthetics. Today’s manufacturers are under continual pressure to deliver perfectly machined metal parts that not only meet demanding tolerances but also boast superior surface finishes and intricate geometries. This growing demand is evident across various sectors, including aerospace and automotive, electronics, renewable energy, and medical device manufacturing. It’s no longer enough to “make it work”; the emphasis is on crafting components that work precisely, every time. Integrating specialized providers, such as high precision metal cutting by Bluegrassbit, has become essential for businesses striving to exceed rigorous benchmarks, ensuring consistency and innovation at every stage of the process.

Precision has a direct impact on every aspect of production and product life. In sectors where safety, efficiency, and reliability are mission-critical, the need for exacting detail cannot be overstated. Whether it’s the wings of a jet, the frame of an electric vehicle, or the chassis for advanced robotics, pursuing high precision is not just about meeting specifications—it’s about ensuring end-user safety, controlling costs, and maintaining a competitive advantage in an intensely crowded global marketplace. The right metal cutting services streamline operations, reduce waste, and offer a sharper competitive edge.

Key Techniques Driving High Precision Metal Cutting

Achieving precision worthy of today’s high-stakes applications depends on a toolkit that’s as diverse as the industries it serves. Cutting-edge techniques such as laser, waterjet, and plasma cutting form the backbone of modern metal fabrication shops, each presenting distinct advantages depending on the material, thickness, and required tolerances. Laser cutting employs concentrated beams of light, delivering peerless accuracy and speed for thin metal sheets—it is especially prized for producing detailed patterns and tight corners with almost no burring or edge distortion. Waterjet cutting leverages a high-pressure stream of water, sometimes mixed with abrasive grit, offering exceptional flexibility and eliminating the risk of heat distortion. This makes it the process of choice for thicker or highly heat-sensitive materials. As highlighted by Metalworking World Magazine, ongoing advancements in cutting technology continue to push the envelope, enabling faster, thicker, and higher-precision cutting than ever before.

- Laser cutting:Excels at detailed, complex geometries for thin-gauge metals and non-metals; delivers rapid, contactless processing with minimal post-processing cleanup.

- Waterjet cutting:Handles a vast array of materials—including metals, ceramics, and glass—without introducing heat-affected zones, preserving the structural integrity of delicate components.

- Plasma cutting:Suited for heavier metals and high-volume industrial fabrication; achieves impressive cutting speeds but with slightly less finesse on fine details.

The art and science of selecting the optimal cutting technique rest on understanding not only the engineering requirements but also downstream factors, such as edge quality, secondary processing needs, safety, and material wastage. Decisions made at this stage have profound implications for the safety, functionality, and lifespan of final products.

Material Diversity and Its Influence on Cutting Processes

The emergence of new metal alloys and composites is reshaping the landscape for high-precision cutting. Metals like titanium, aluminum, and specially engineered steels bring unique properties—strength, lightness, corrosion resistance—but also pose fresh challenges for machinists and engineers. The methods that work flawlessly on mild steel may warp, pit, or crack more exotic materials.

Aerospace-grade titanium, for example, requires specially calibrated cutting speeds and cooling techniques to prevent the induction of microcracks, which could compromise component integrity during flight. Medical-grade stainless steel requires flawless finishes, free from even the slightest imperfections, to ensure patient safety. With the materials palette expanding, a deep understanding of metallurgical science is now as valuable to metal cutting as the most advanced machine tools themselves, ensuring every job meets specifications without compromise.

The Role of Automation and Digital Transformation

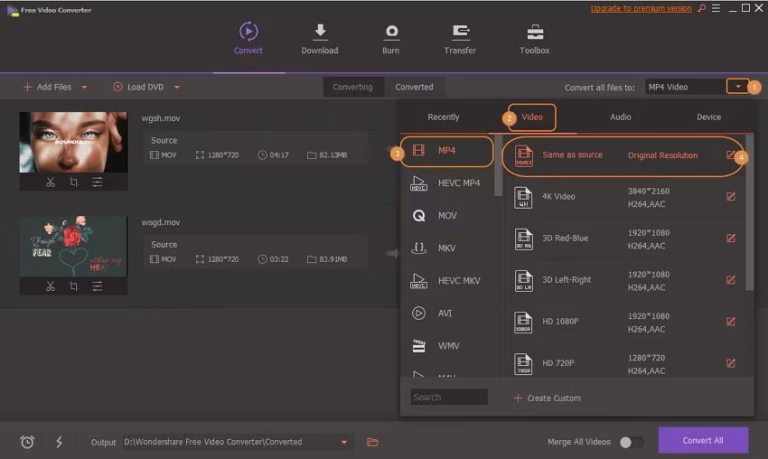

A wave of digital and robotic technologies is revolutionizing modern metal cutting. Automated CNC machines and robotics handle the most repetitive and precise tasks, executing cuts with remarkable repeatability and speed. With software-driven workflows, engineers can upload digital blueprints, simulate cutting paths, and let machines do the rest, freeing skilled operators to focus on programming, maintenance, and quality assurance.

This transition is underscored by the impact of robotics on metal fabrication, which has reshaped workflows across manufacturing facilities. Robotics enhances operator safety by taking on hazardous tasks, reduces workplace injuries, and ensures that tolerances remain consistent across high-volume, multi-shift operations. Combined with AI-powered monitoring, real-time data analytics enable predictive maintenance and instant deviation alerts, keeping defect rates to a minimum and significantly extending equipment life.

Quality Assurance: Ensuring Consistency Across Production

True precision in metal cutting is measured not just in microns but also in reliability from the first to the last piece off the line. Facilities rely on rigorous quality assurance protocols, utilizing state-of-the-art inspection tools like coordinate measuring machines (CMMs), 3D scanners, and automated vision systems. These technologies capture detailed data on each part, ensuring every dimension aligns with customer and regulatory requirements.

In addition to advanced tools, global quality standards such as ISO 9001 and AS9100 drive continuous process improvement and risk management throughout the production cycle. Regular audits, documentation, and training reinforce a culture of precision and accountability, providing customers with peace of mind who require the highest standards in every shipment.

Challenges and Solutions in Achieving High-Precision Outcomes

The pursuit of micrometer-perfect cuts comes with its share of obstacles. Cutting tools degrade over time, and even minute variations in temperature or vibration can introduce errors. Machines prone to subtle misalignments or inconsistent feed speeds may create defects invisible to the naked eye but unacceptable in critical applications. To counter these risks, high-precision shops employ diligent maintenance routines, environmental controls such as temperature-regulated workspaces, and real-time sensor feedback to correct deviations immediately.

Many also experiment with hybrid approaches—combining waterjet roughing with laser finishing, or integrating additive manufacturing steps—to optimize both speed and accuracy. By encouraging creative problem-solving and maintaining a relentless focus on both process and product, top manufacturers deliver flawless results for even the most demanding projects.

The Environmental Side of Metal Cutting

The shift toward sustainability is evident in contemporary metal cutting. Companies now select technologies specifically to minimize energy consumption and material waste. Waterjet cutting, for instance, produces no hazardous fumes and allows abrasive materials to be reclaimed or recycled. State-of-the-art filtration systems trap airborne particles from plasma and laser cutting, reducing the environmental footprint.

Process optimization and scrap reduction are more than “green” talking points—they provide real operational savings, decrease supply chain costs, and align with increasing pressure from both regulators and conscientious clients to pursue greener production methods.

What’s Next? Future Trends in High Precision Metal Cutting

Looking to the future, the trends underpinning high precision metal cutting point to an industry poised for further transformation. Materials science will continue to push boundaries, introducing lighter, stronger, and more complex alloys that demand innovative cutting techniques. Machines driven by AI and advanced analytics will increasingly adjust parameters in real-time, learning from historical data to minimize waste, energy consumption, and the need for operator intervention. Ultimately, as production cycles accelerate and customers demand ever-greater precision, the manufacturers who thrive will be those that eagerly embrace innovation, sustainability, and a relentless commitment to quality, delivering metal parts that shape the future of numerous industries.