Understanding Pipeline Pigging

Pipeline pigging is a critical maintenance process in the oil, gas, and water distribution industries. This method utilizes specially designed devices called “pigs” to clean, inspect, and ensure the smooth operation of pipelines. As these devices traverse the interior of pipelines, propelled by the system’s flow or external means, they perform various functions: removing debris, identifying pipeline defects, and even gathering operational data. Pigging is not just about cleanliness; it upholds safety standards and extends the life of expensive infrastructure.

For pigging to be genuinely effective, operators must rely on essential pigging accessories for pipeline cleaning. These accessories can make all the difference between routine pipeline maintenance and a costly disruption caused by undetected fouling or wear. The right accessories ensure that the cleaning and inspection processes are efficient, thorough, and safe for personnel and the environment.

The upkeep of pipeline systems has never been more vital. As energy demand grows and regulations tighten, efficient maintenance strategies help prevent pipeline failures, which could otherwise lead to environmental incidents or service interruptions. When paired with the right technology, pigging operations reinforce pipeline reliability while supporting operational efficiency.

Advancements in pigging accessories have transformed traditional models into innovative, data-driven solutions. Integrating sensors and digital innovations allows operators to proactively identify risks, manage product flow, and plan targeted maintenance activities that reduce operational downtime.

Selecting the appropriate accessories is central to successful pigging operations. Some of the most essential pigging accessories include:

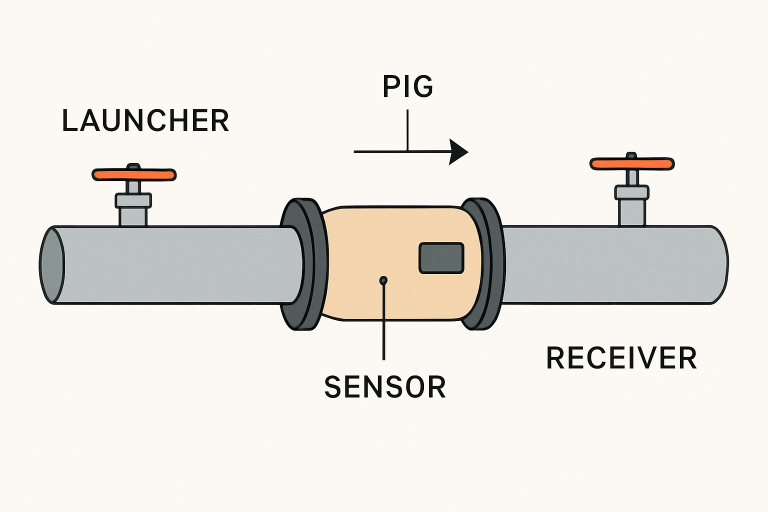

- Pig Launchers and Receivers: These specialized fittings enable safe insertion and removal of pigs from the pipeline, minimizing the risk of contamination or environmental exposure.

- Pig Detectors: Designed to confirm the passage, arrival, and location of pigs as they traverse the pipeline, ensuring the operation is proceeding as planned.

- Sealing Discs and Cups create a secure interface between the pig and the pipeline wall, maximizing cleaning efficiency and reducing debris bypass.

- Brushes and Scrapers: Attachments that dislodge resilient debris, scale, and other contaminants adhered to the pipeline’s inner surface.

Innovations in Pigging Accessories

In recent years, technological advancements in pigging accessory design have surged. Innovative pigging accessories now have diagnostic sensors, data logging capabilities, and wireless communication features. These upgrades enable real-time monitoring and more accurate detection of anomalies such as corrosion, cracks, and wall thickness changes.

Some intelligent systems utilize artificial intelligence and machine learning algorithms to analyze vast amounts of operational data, helping operators shift from reactive to predictive maintenance. This level of innovation not only enhances asset reliability but also supports regulatory compliance and environmental stewardship.

Benefits of Smart Pigging Accessories

- Enhanced Safety: Real-time data and early detection of anomalies help prevent leaks or ruptures, protecting personnel, communities, and ecosystems.

- Cost Efficiency: Predictive maintenance enabled by innovative accessories minimizes emergency repairs and extends the interval between costly shutdowns.

- Data-Driven Decision Making: Access to comprehensive operational data allows for more informed, strategic maintenance planning and resource allocation.

These benefits contribute to safer, more sustainable, cost-effective pipeline operations—key priorities in today’s industrial landscape. The Pipeline and Hazardous Materials Safety Administration’s resources provide valuable insights for a deeper exploration into safety standards and regulations.

Choosing the Right Accessories

The selection of pigging accessories depends on factors such as pipeline diameter, material, transported products, and operational environments. Careful assessment of specific operational needs is crucial. For example, pipelines that carry abrasive products benefit from pigs with reinforced brushes and scrapers, whereas systems exposed to corrosive materials require accessories manufactured with resistant alloys or coatings.

Collaboration with accessory manufacturers and pigging experts can help operators tailor solutions to unique challenges, optimize system performance, and ensure compliance with industry standards.

Best Practices for Pigging Operations

- Regular Scheduling: Pipelines should be pigged according to a plan based on pipeline throughput, product characteristics, and regulatory guidance.

- Comprehensive Staff Training: To ensure consistent, safe execution, personnel must receive ongoing training in pigging operations, troubleshooting, and safety protocols.

- Robust Data Management: Leveraging digital data from pigging accessories allows operators to track pipeline condition trends, optimize asset utilization, and plan maintenance efficiently.

Adopting these practices, as recommended by industry experts, helps prevent avoidable failures and supports regulatory compliance. Resources such as Wikipedia’s article on Pigging offer further guidance on pigging fundamentals and evolving industry standards.

Future Trends in Pigging Technology

The future of pigging technology points towards even greater integration with the Industrial Internet of Things (IIoT) and artificial intelligence. These trends will result in advanced sensors, wireless monitoring systems, and seamless data integration across operational platforms. Operators can expect more sustainable materials to be adopted in pigging accessories, which aligns with global sustainability and emissions reduction goals.

As these innovations become standard practice, pipeline operators will be better positioned to protect their assets, meet regulatory demands, and minimize environmental impact, while maintaining the reliability required to keep global supply chains moving.

Continual investment in smart solutions for pigging operations enhances operational efficiency and safety and prepares infrastructure owners for the evolving technological landscape in the energy and utility sectors.